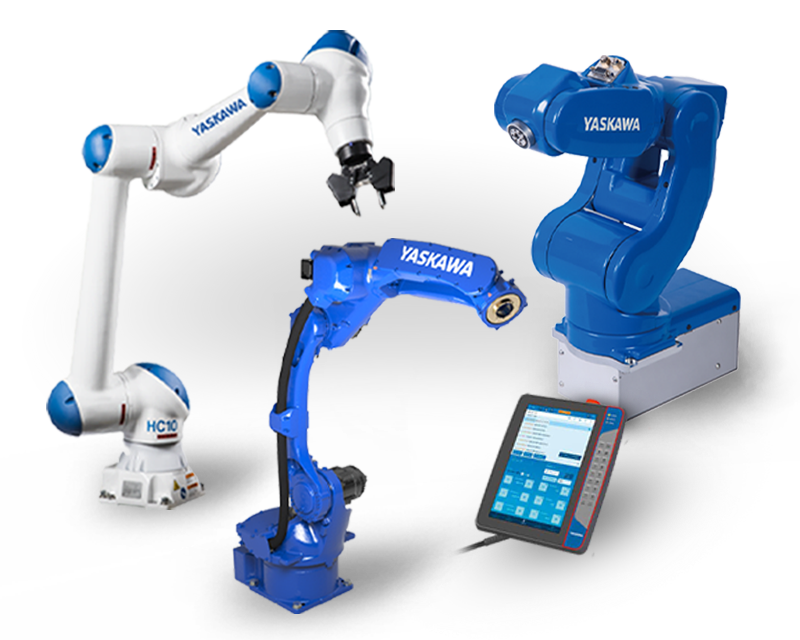

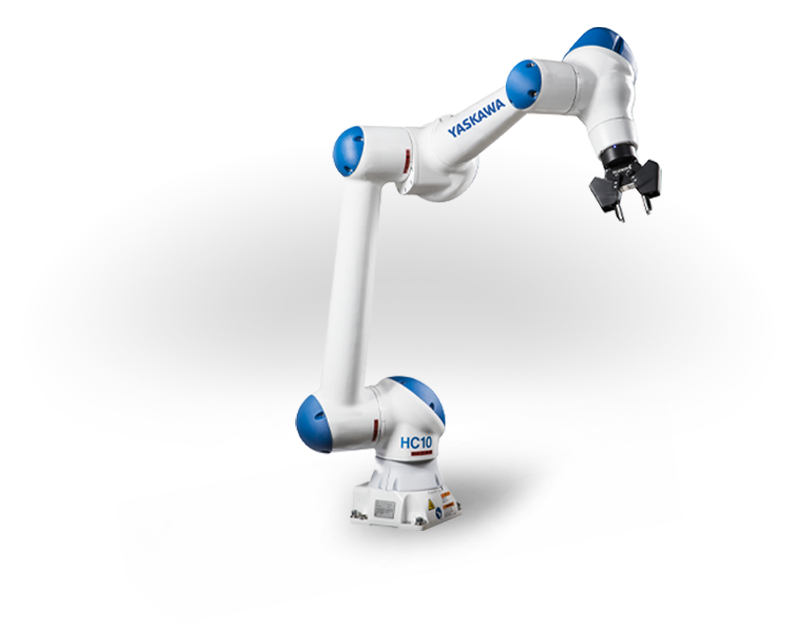

Optimize manufacturing safety and efficiency with industrial collaborative robots.

Are you a manufacturer branching out into robotics? Yaskawa’s Smart Series offers simple, intuitive robot programming for novice programmers without significant upfront investment in training.